Reshaping the sterilization world

With its unrivalled low consumption, Supreme is the new market benchmark.

![]() 17l

17l

![]() 22l

22l

![]() 28l

28l

Consumption is approx. 100 ml/cycle

We developed the first closed-loop sterilizer that uses mains through a specific internal filtration system that recycles water to be reused in the following cycles. This performance eliminates waste, reduces costs and ensures a significant increase in the efficiency of any modern dentistry surgery. It also solves all issues relating to demineralised water storage and supply.

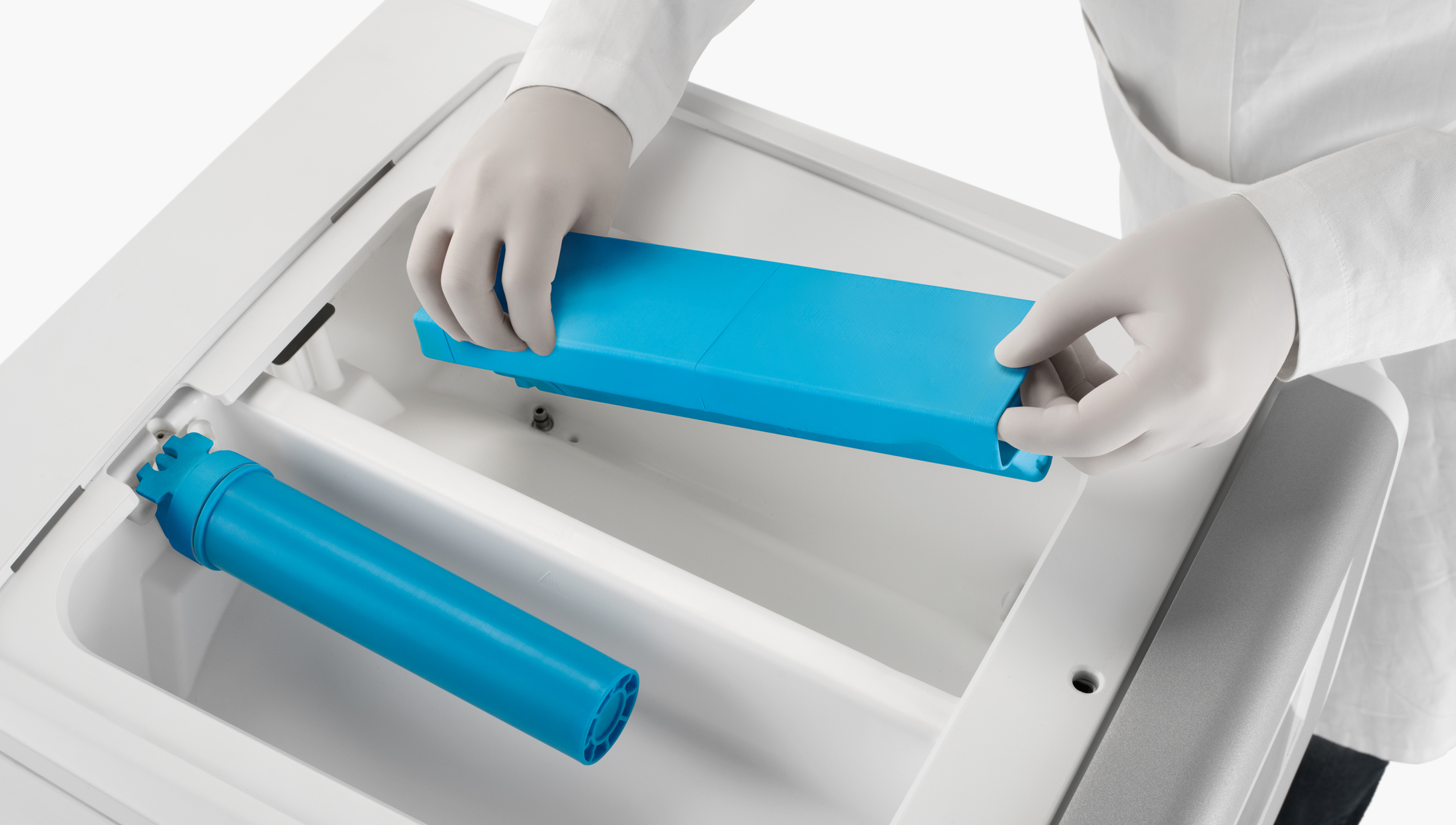

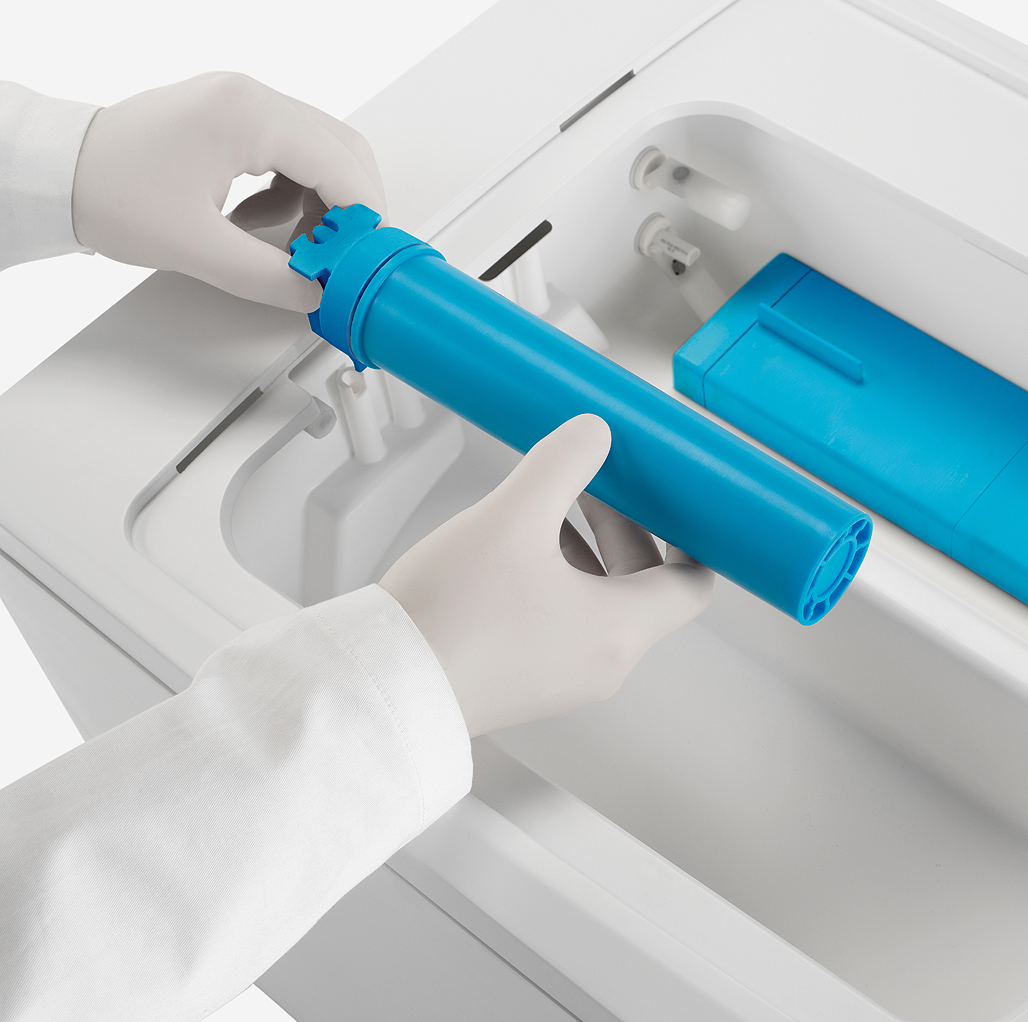

Unlike traditional sterilizers, Supreme does not require any external water connection for mains water treatment. Thanks to the demineralisation filter on the main tank, the user can fill the latter with plain tap water, thereby significantly optimising spaces, streamlining processes and achieving considerable savings. Supreme’s different filtration systems guarantee unprecedented ease of operation.

The nano-ceramic recirculation filter, incorporated into the secondary tank, makes it possible to distil and purify water so that it can be reused in the following sterilization cycle. The built-in conductivity sensor ensures compliance with water quality parameters as it protects the machine internal components from excess lime. Total consumption is 5 litres per 50 cycles, meaning approx. 100 ml/cycle, a real revolution.

The 7” touch screen is as user-friendly as a tablet

The size of the display, its performance and the research carried out to develop the user interface make the sterilizer simple and ready-to-use. Supreme’s video tutorials and light indicators turn it into a unique sterilizer.

Supreme can also communicate through colours. A door built-in LED bar provides immediate information to the user about the machine status, changing colours according to the different work phases. The user will be able to understand at a glance which is the current process phase of the sterilizer, even at a distance.

Through its colour display, Supreme provides video tutorials and important information for using and maintaining the machine. Everything is explained in simple videos: from information about load positioning to instructions for filter replacement. A personal assistant providing support to all operators.

An incorporated WiFi system to use the cloud

At the end of each sterilization cycle, the machine stores a report inside its memory.

The user can download the cycles in PDF format at any time through the front USB port or automatically store them in the cloud using the WiFi and Di.V.A. system.

All sterilizers of the Supreme range are equipped with incorporated WiFi and Ethernet port. Connected to the Internet by enabling the Easy Check service, they can receive remote support. Intervention times can be significantly reduced thereby allowing technicians to keep machines constantly efficient.

MyTrace is Cefla’s traceability software supplied with Supreme. By using this programme, each set of sterilized instruments can be associated to the patient through a bar code. This essential software completes the sterilization process and provides legal protection to dentists.

A full range of accessories to expand Supreme's functions.

It is the first cloud-based control and traceability system for MOCOM sterilization devices.